Dec 2025

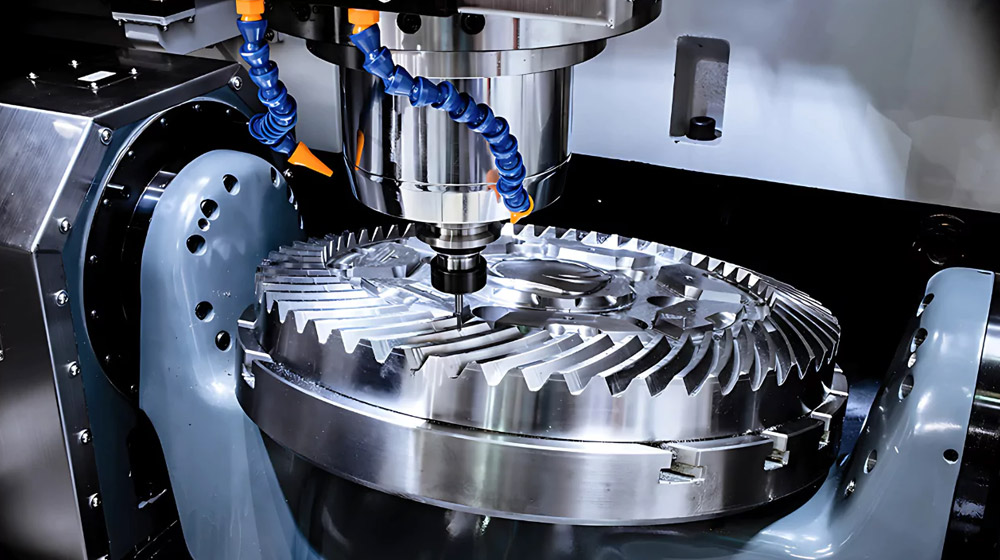

In today’s manufacturing environment, precision is not just a competitive differentiator; it’s an absolute requirement. Whether in aerospace, automotive, complex prototype development, or larger production runs, industries are now looking for components that can meet tight tolerances and do so efficiently. Carver Roboweld LTD sees this need and has accepted the challenge of providing a solution; we have made the investment in 5-axis CNC machining which takes accuracy, complexity and productivity to completely different levels.

So what exactly is 5-axis CNC machining, and when should you use it? Here’s the breakdown.

CNC (Computer Numerical Control) machines are subtractive manufacturing processes where material is removed from a solid block with tools that move in straight lines. Because traditional CNC machining is limited to 3-axes (X, Y and Z) for movement possibilities, it can seem overly simplistic for many parts. 3-axis CNC can deliver complexity, undercuts, or any intricate geometry or design limitation needed, but it will take longer to deliver the part because more set-up would be required on complicated designs.

5-axis CNC machining introduces two more rotational movements that are within an axial coordinate system:

A-axis: Rotation around the X-axis

B-axis: Rotation around the Y-axis.

This enables the cutting tool to approach the work piece from most any angle without multiple set ups. For Carver Roboweld LTD, this means that we can make highly complex parts faster, with fewer mistakes and far less limitation as it relates to design limitations.

Although 5-Axis CNC machining is an advanced capability, it is not an absolute requirement for every job. The following are critical times that it is appropriate to use:

1. Very Complex Geometries

If your component has complex outlines, deep holes, or angles that are compound in nature, then 5-Axis machining can take care of it with very little trouble. This capability is very important in respect to airframes in the aerospace industry, medical devices, and defense manufacturing.

2. Tighter Tolerances and Precision

As the tolerances get down to microns, any minor change in repositioning can be very expensive if your part is dimensional. 5-Axis machining allows Carver Roboweld to minimize set ups, which in turn greatly decreases the risk of getting the dimensions inaccurate.

3. A Shorter Production Time

5-Axis machining allows us to machine multiple sides of a part in one set up, meaning we have less re-positioning when moving a component around. This is a considerable time savings and we can accommodate any rush jobs in most cases without compromising on quality or service.

4. Complex Surface Finish

If your plan has to have extremely smooth or contoured surfaces, such as turbine blades or mold components, 5-Axis machining allows for an even finish in fewer passes.

5. Custom Prototyping

Prototyping, from my experience, requires flexibility. Using 5-Axis machining, we can easily adjust designs or amend tool paths quickly, providing our customers with a much quicker route from concept to functioning prototype.

Both technical and financial advantages come with 5-axis CNC machining. We assist clients in saving time and money in production by cutting lead times, minimising manual setups, and attaining near-perfect accuracy. For industries characterized by rapid and continual innovation, the flexibility to produce highly complex parts with high quality and speed can mean the difference between being a market leader and falling behind.

Five-axis More than just an improvement in manufacturing, CNC machining is a development of projects that call for intricate, precise, and effective solutions. From concept to delivery, Carver Roboweld LTD helps our clients design and create their most difficult products by utilising 5-axis technology.

Contact the knowledgeable staff at Carver Roboweld LTD to learn how our 5-axis CNC machining can meet the demanding quality and efficiency requirements of your upcoming project.